Contents

- I. Preparation

- II. Identifying the Appliance and Refrigerant Type

- III. Recovering R-410A

- IV. Safety Precautions

- V. Proper Handling and Storage of Recovered R-410A

- VI. Disposal or Reuse of Recovered R-410A

- VII. Performing Leak Tests and Repairs

- VIII. Recharging the Appliance with R-410A

- IX. Documentation and Record-Keeping

- X. Training and Certification

Have you ever wondered what happens to the R-410A refrigerant in your appliances when it needs to be recovered? “The Process of Recovering R-410A from an Appliance” provides an insightful look into how this essential substance is safely and efficiently extracted. Whether you’re a curious consumer or an appliance technician, this article will guide you through the steps involved in recovering R-410A, ensuring that you stay informed about the environmental impact and proper handling of this refrigerant.

I. Preparation

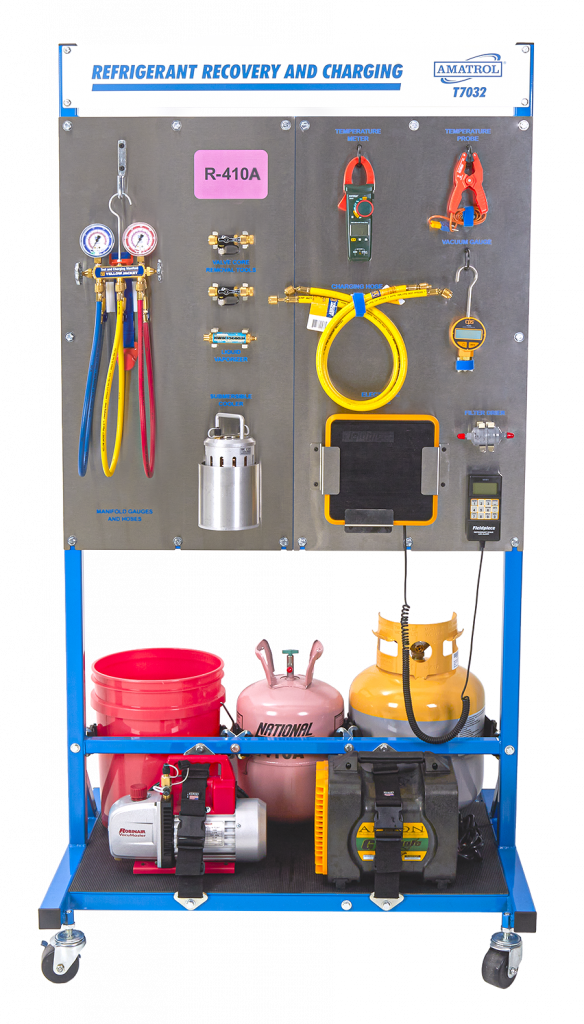

A. Gather necessary tools and equipment

Before starting the process of recovering R-410A from an appliance, you need to gather all the necessary tools and equipment. This includes a recovery machine, recovery hoses, gauges, valve cores, and a certified refrigerant reclaimer. It is important to ensure that all the tools and equipment are in good working condition and properly calibrated to accurately recover the refrigerant.

B. Ensure proper safety precautions

Safety should be a top priority when handling any refrigerant, including R-410A. Before starting the recovery process, it is important to take proper safety precautions. This includes wearing appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a respirator. Additionally, ensure that the work area is well-ventilated to avoid inhaling any harmful gases during the recovery process. Lastly, adhere to local regulations and guidelines to ensure compliance with any safety requirements and protocols.

II. Identifying the Appliance and Refrigerant Type

A. Determine if the appliance contains R-410A refrigerant

Before proceeding with the recovery process, it is crucial to determine whether the appliance contains R-410A refrigerant. This can usually be found in the manufacturer’s manual or on the appliance’s label. If the information is not readily available, you can consult with the manufacturer or a qualified technician to confirm the refrigerant type.

B. Verify the manufacturer’s specifications

Once you have determined that the appliance contains R-410A refrigerant, it is important to verify the manufacturer’s specifications. The manufacturer’s specifications will provide guidance on the appropriate recovery procedure for that specific appliance. It is important to follow these specifications to ensure the safe and effective recovery of R-410A.

III. Recovering R-410A

A. Shut down the appliance

Before initiating the recovery process, it is important to shut down the appliance properly. This involves turning off the power to the appliance and allowing it to cool down. Follow the manufacturer’s instructions to ensure that the appliance is shut down correctly.

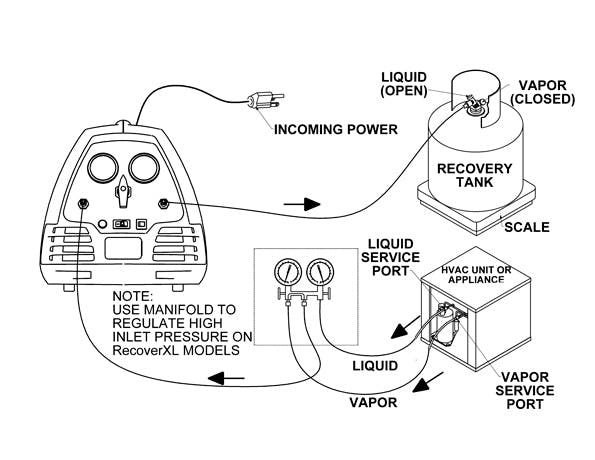

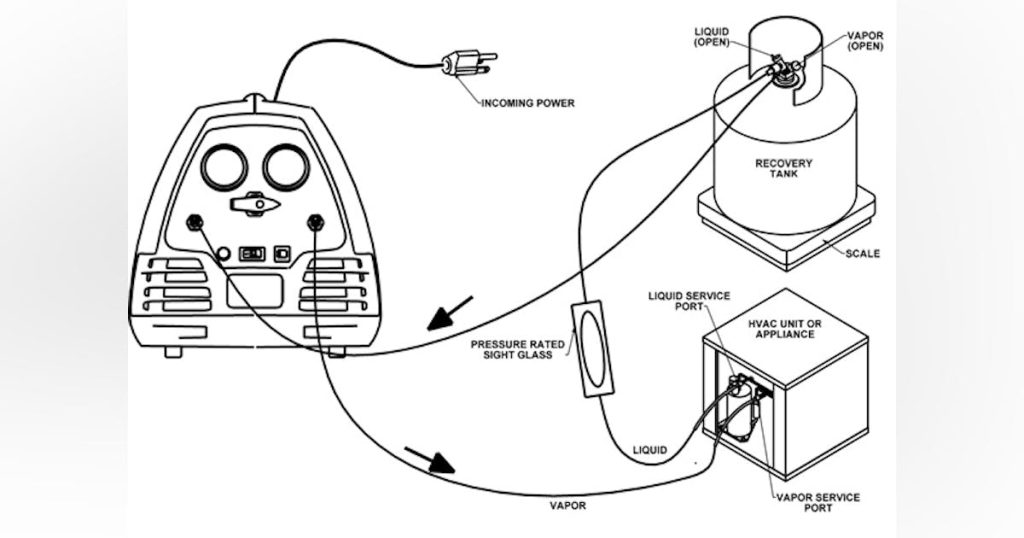

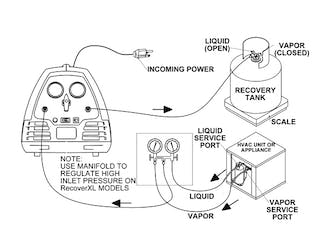

B. Connect the recovery machine to the appliance

Once the appliance is shut down, you can connect the recovery machine to the appliance. Make sure to use the appropriate fittings and connections to ensure a secure and leak-free connection.

C. Purge the recovery hoses

Before opening the access valves, it is important to purge the recovery hoses. This helps remove any air or moisture that may have accumulated in the hoses, ensuring a more efficient recovery process. Follow the manufacturer’s instructions on how to properly purge the recovery hoses.

D. Open the access valves

After purging the recovery hoses, you can proceed to open the access valves on the appliance. This allows the recovery machine to establish a connection with the appliance’s refrigerant system. Take caution to ensure that the valves are fully open and not leaking.

E. Initiate the recovery process

Once the access valves are open, you can initiate the recovery process on the recovery machine. Follow the manufacturer’s instructions on how to operate the recovery machine properly. The recovery machine will start removing the R-410A refrigerant from the appliance’s system and transfer it into the recovery machine’s storage tank.

F. Monitor the recovery process

During the recovery process, it is important to closely monitor the progress. Keep an eye on the gauges and ensure that the recovery machine is operating within the manufacturer’s specified parameters. If any abnormal readings or issues arise, stop the recovery process and assess the situation before proceeding.

G. Complete the recovery process

Once the recovery machine has extracted the majority of the R-410A refrigerant from the appliance, you can proceed to complete the recovery process. Follow the manufacturer’s instructions on how to properly shut down the recovery machine and disconnect it from the appliance.

IV. Safety Precautions

A. Wear appropriate personal protective equipment (PPE)

Safety should always be a top priority when working with refrigerants. When performing the recovery process, make sure to wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a respirator. These precautions help protect you from any potential risks or exposure to harmful gases.

B. Follow proper ventilation requirements

To ensure a safe working environment, it is important to follow proper ventilation requirements. Adequate ventilation helps prevent the accumulation of any harmful gases during the recovery process. Open windows or use fans to increase air circulation in the area where the recovery process is taking place.

C. Adhere to local regulations and guidelines

Different regions and jurisdictions may have specific regulations and guidelines when it comes to handling and recovering refrigerants. It is important to adhere to these regulations to ensure compliance and maintain a safe working environment. Be familiar with local regulations and guidelines, and make sure to follow them throughout the recovery process.

V. Proper Handling and Storage of Recovered R-410A

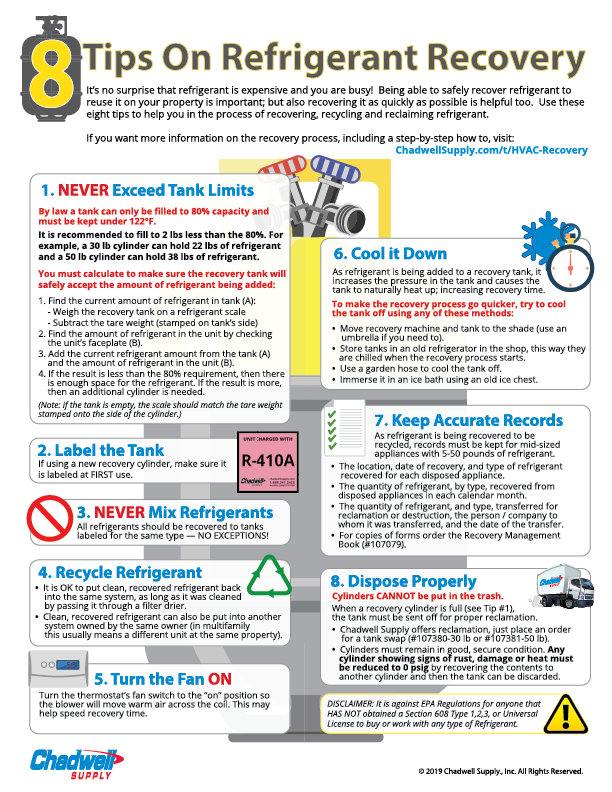

A. Transfer the recovered refrigerant to appropriate containers

After completing the recovery process, it is important to transfer the recovered R-410A refrigerant to appropriate containers. Use containers that are specifically designed for storing refrigerants and ensure that they are properly sealed and labeled.

B. Label the containers properly

To maintain proper identification and prevent any mix-ups, it is crucial to label the containers properly. Clearly label the containers with the type of refrigerant, in this case, R-410A, and include any additional information required by local regulations and guidelines.

C. Store the containers in a designated area

To ensure safety and prevent any accidental leaks or damage, it is important to store the containers in a designated area. This area should be well-ventilated, secure, and away from any potential sources of ignition. Make sure that the containers are stored upright and away from direct sunlight or extreme temperatures.

VI. Disposal or Reuse of Recovered R-410A

A. Check local regulations and guidelines

Before deciding on the disposal or reuse of the recovered R-410A refrigerant, it is important to check local regulations and guidelines. Different regions may have specific requirements for the proper disposal or reuse of refrigerants. Make sure to comply with these regulations to ensure environmental protection and safety.

B. Determine the condition of the recovered refrigerant

Assessing the condition of the recovered R-410A refrigerant is an important step in determining whether it can be reused or if it requires proper disposal. If the refrigerant is still in good condition and meets the necessary specifications, it may be eligible for reuse. However, if the refrigerant shows signs of contamination or degradation, it should be disposed of properly.

C. Consult with a certified refrigerant reclaimer

If you are unsure about the condition or best course of action for the recovered R-410A refrigerant, it is recommended to consult with a certified refrigerant reclaimer. These professionals have the knowledge and expertise to assess the refrigerant’s condition and provide guidance on whether it can be reused or if it requires proper disposal.

D. Arrange for proper disposal or reuse

Based on the assessment and guidance from a certified refrigerant reclaimer, you can proceed to arrange for the proper disposal or reuse of the recovered R-410A refrigerant. Follow the recommended procedures and protocols to ensure compliance with local regulations and guidelines.

VII. Performing Leak Tests and Repairs

A. Conduct a leak test on the appliance

After the recovery process and before recharging the appliance, it is important to conduct a leak test. A leak test helps identify any potential leaks in the appliance’s refrigerant system. Use appropriate leak detection tools and methods recommended by the manufacturer or in accordance with industry standards.

B. Locate and repair any leaks found

If any leaks are detected during the leak test, it is crucial to locate and repair them before proceeding. Leaks can cause the loss of refrigerant and negatively impact the performance of the appliance. Address any leaks found using appropriate repair methods and materials.

C. Conduct a final leak test

After repairing any identified leaks, it is important to conduct a final leak test to ensure that all leaks have been properly addressed. This test provides confidence that the appliance’s refrigerant system is free from leaks and ready for recharging.

VIII. Recharging the Appliance with R-410A

A. Evacuate the appliance

Before recharging the appliance with R-410A refrigerant, it is necessary to evacuate the appliance’s refrigerant system. Evacuation helps remove any moisture or air that may have entered the system during the recovery process. Follow the manufacturer’s instructions on how to properly evacuate the appliance.

B. Weigh or measure the proper charge of R-410A

To ensure the proper and accurate charging of R-410A refrigerant, it is important to weigh or measure the appropriate charge. This ensures that the appliance is not overcharged or undercharged, which can affect its performance. Follow the manufacturer’s specifications and guidelines on the appropriate charge for the specific appliance.

C. Add the refrigerant to the appliance

Once the proper charge has been measured or weighed, you can proceed to add the R-410A refrigerant to the appliance. Use the appropriate fittings and connections to ensure a secure and leak-free transfer of refrigerant into the appliance’s system.

D. Perform a pressure test

After adding the refrigerant, it is important to perform a pressure test to ensure that the appliance’s refrigerant system is properly sealed and operates within the manufacturer’s specified parameters. This test helps identify any potential issues or leaks that may have been missed during the earlier leak tests.

E. Verify proper operation

Once the pressure test has been successfully completed, it is crucial to verify the proper operation of the appliance. Check that all functions and components are working as expected and monitor the appliance for any abnormal behavior. This ensures that the appliance is ready for use and meets the necessary performance standards.

IX. Documentation and Record-Keeping

A. Maintain accurate records of the recovery process

Throughout the entire recovery process, it is important to maintain accurate records. This includes documenting details such as the date and time of the recovery process, the location, the appliance’s information, and any other relevant information. These records provide a valuable reference for future maintenance, inspections, or compliance audits.

B. Include details such as date, time, and location

When documenting the recovery process, make sure to include specific details such as the date, time, and location. This helps establish a timeline and provides a clear record of when and where the recovery process took place. These details are important for compliance purposes and future reference.

C. Document any issues or observations

During the recovery process, it is important to document any issues or observations that arise. This can include any abnormalities in the appliance’s refrigerant system, leaks found, or any other relevant information. Proper documentation helps in troubleshooting, identifying recurring issues, and maintaining a comprehensive record of the appliance’s history.

X. Training and Certification

A. Ensure technicians are properly trained on recovery procedures

To ensure the safe and effective recovery of R-410A and compliance with regulations, it is crucial to ensure that technicians are properly trained on recovery procedures. Training should cover all aspects of the recovery process, including safety protocols, equipment operation, and proper handling of refrigerants. Regular refresher training is also beneficial to keep technicians updated on any changes in industry standards or regulations.

B. Obtain necessary certifications

In addition to proper training, technicians should obtain necessary certifications to handle and recover refrigerants, including R-410A. These certifications validate the technician’s knowledge and competency in handling refrigerants safely and in accordance with regulations. Certifications may be obtained through accredited training programs or certification bodies.

C. Stay updated on industry standards and regulations

The field of refrigeration and air conditioning is constantly evolving, with new technologies, standards, and regulations being introduced. It is important for technicians to stay updated on these changes to ensure they are working in compliance with the latest industry standards and regulations. Stay informed through professional associations, industry publications, and continuous education programs to keep up with the latest developments.

In conclusion, the process of recovering R-410A from an appliance involves careful preparation, identification of the appliance and refrigerant type, following proper procedures for recovery, adhering to safety precautions, and ensuring compliance with regulations. By following these steps and maintaining accurate documentation, technicians can safely and effectively recover R-410A while minimizing any potential risks or environmental impact. Continuous training and certification help ensure that technicians are equipped with the necessary knowledge and skills to perform the recovery process correctly and stay in compliance with industry standards and regulations.