Contents

You’re about to discover the fascinating behind-the-scenes details of the iconic Jordan sneakers. Have you ever wondered how much it actually costs to manufacture a pair of Jordans? Brace yourself as we unravel the intriguing world of sneaker production and delve into the intricate expenses involved. From materials to labor, we’ll provide a closer look at the intricate web that determines the cost of manufacturing these highly coveted sneakers. Get ready to uncover the secrets behind the creation of your favorite kicks.

Research and Development

Design and Concepts

When it comes to the manufacturing of Jordans, the process begins with extensive research and development. The design and concept phase involves exploring new ideas, trends, and styles to create innovative and attractive footwear. Designers work tirelessly to come up with unique designs that capture the essence of the Jordan brand while also meeting the demands and preferences of the target market.

Prototyping and Testing

Once the initial design concepts are created, the prototyping and testing stage begins. This involves creating physical prototypes of the shoes to assess their functionality, durability, and overall design. The prototypes are put through rigorous testing to ensure they meet the high-quality standards associated with the Jordan brand. Any necessary adjustments are made during this phase to ensure the shoes are perfect before moving on to production.

Material Selection

The selection of materials is a crucial aspect of manufacturing Jordans. Quality materials, such as leather, rubber, and textiles, are carefully chosen to ensure the shoes are not only comfortable but also durable. The materials must be able to withstand the wear and tear of everyday use and maintain their aesthetic appeal. Additionally, adhesives are selected to ensure strong bonds between different materials during the assembly process for a long-lasting and reliable final product.

Raw Materials

Leather

Leather is an essential raw material used in the production of Jordans. The quality and type of leather selected play a significant role in the overall appearance, comfort, and durability of the shoes. The leather is carefully sourced and processed to meet the high standards expected from Jordan footwear. Different leather finishes and textures are used to create a range of styles and designs, catering to various consumer preferences.

Rubber

Rubber is another vital raw material used in the manufacturing of Jordans. It is primarily used for the outsoles, providing traction and grip. The rubber used in Jordans is of high quality to ensure excellent performance and longevity. The selection of the right rubber compounds is essential to create outsoles that offer optimal cushioning, flexibility, and durability for an exceptional wearing experience.

Textiles

Textiles, such as fabrics and synthetic materials, are also extensively used in the manufacturing of Jordans. They are utilized for various components, including the upper part of the shoe, linings, and padding. Textiles provide breathability, comfort, and flexibility to the shoes, ensuring a comfortable fit for the wearer. Different types of textiles are used based on the specific design and performance requirements of each shoe model.

Adhesives

Adhesives play a crucial role in the assembly of Jordans, ensuring that different parts of the shoes are securely bonded together. High-quality adhesives are chosen to provide strong and durable connections between the various components of the shoe, including the upper, midsole, and outsole. The selection of the right adhesives is essential to maintain the shoe’s structural integrity and longevity.

Production Process

Cutting and Stitching

The production process of Jordans involves cutting the various raw materials, such as leather and textiles, into specific shapes and sizes according to the shoe design. Highly skilled workers use cutting tools to ensure precision and accuracy in this stage. Once the materials are cut, they are stitched together using specialized sewing machines, creating the shoe’s upper part. This process requires attention to detail and expertise to achieve the desired fit and appearance.

Lasting and Finishing

After the upper part of the shoe is stitched together, it undergoes the lasting process. Lasting involves stretching the upper over a mold, referred to as a last, to give the shoe its final shape. The lasting process requires careful craftsmanship to achieve the desired fit and aesthetics. Once the lasting is complete, the shoes go through finishing touches, including cleaning, polishing, and applying any necessary coatings or treatments to enhance their appearance and durability.

Moulding and Casting

In some Jordan models, moulding and casting techniques are employed to create specific components. This process involves using molds and specialized equipment to shape materials such as rubber and plastic. Moulding is used, for example, to create the midsole or other structural components. Casting may be utilized for adding decorative elements or unique details to the shoes. These techniques add to the complexity and cost of manufacturing Jordans but contribute to their distinctiveness and appeal.

Assembly

The final manufacturing stage involves the assembly of all the components, including the upper, midsole, outsole, and any additional features. Skillful workers meticulously align and attach the different parts, ensuring each shoe meets the brand’s high standards. This labor-intensive process requires attention to detail and precision to deliver the iconic aesthetic and functionality associated with Jordans.

Labor Costs

Worker Salaries

The cost of labor plays a significant role in the overall manufacturing costs of Jordans. Skilled workers involved in the cutting, stitching, lasting, finishing, and assembly processes require competitive salaries commensurate with their expertise and contributions. The labor costs account for the meticulous craftsmanship required to create each pair of Jordans, ensuring consistent quality and attention to detail.

Working Conditions

Creating a safe and comfortable working environment for the labor force involved in the manufacturing process is crucial. Adequate ventilation, proper lighting, and ergonomically designed workstations are provided to ensure worker well-being and productivity. Compliance with labor laws and regulations also contributes to the overall labor costs.

Skill Level

The production of Jordans requires a high level of skill and expertise. Skilled workers who possess the necessary craftsmanship and attention to detail are essential to create shoes of outstanding quality. Due to the specialized nature of the work, labor costs may be higher than in other industries. The level of skill required ensures that each pair of Jordans is meticulously crafted and meets the brand’s high standards.

Machinery and Equipment

Sewing Machines

Sewing machines are an integral part of the footwear manufacturing process. The selection and maintenance of high-quality sewing machines contribute to the overall production costs. These machines are utilized for stitching the various components of the shoes, ensuring accuracy and durability. Regular servicing and replacement of sewing machine parts also factor into the machinery and equipment expenses.

Cutting Tools

Cutting tools, such as knives and scissors, are essential for precisely cutting the raw materials during the production process. Ensuring that these tools are of the highest quality and well-maintained is crucial for achieving accurate cuts and minimizing material waste. The cost of purchasing and maintaining cutting tools is an important consideration in the manufacturing expenses.

Moulding Equipment

In models that require moulding techniques, specialized equipment is necessary to shape rubber, plastic, or other materials. The machinery used for moulding adds an additional expense to the production process. Upkeep and maintenance of the equipment are vital to ensure accurate and consistent results, contributing to the overall cost of manufacturing Jordans.

Overhead Expenses

Utilities

Various utilities, including electricity, water, and heating, contribute to the overhead expenses in the manufacturing process. These utilities are crucial for powering the machinery and equipment, maintaining optimal working conditions, and ensuring a smooth production process. Monitoring and managing utility usage help control overhead costs effectively.

Rent and Maintenance

Renting production facilities and maintaining them to meet the required standards contribute to the overhead expenses of manufacturing Jordans. The size and location of the facilities, as well as the upkeep and repairs, are factors that impact the overall manufacturing costs. Creating a conducive and functional workspace adds value to the manufacturing process.

Transportation

Transportation costs encompass the movement of raw materials from suppliers to the manufacturing facility and the transportation of finished products to distribution centers or retail partners. Efficient transportation logistics and reliable shipping services are essential for timely and cost-effective operations. Managing transportation expenses is crucial to optimizing the overall manufacturing expenses.

Packaging

The cost of packaging materials, such as boxes, labels, and inserts, is another aspect of overhead expenses. Packaging plays a vital role in protecting the shoes during transportation and presenting the final product to consumers. Designing and producing attractive and functional packaging that aligns with the Jordan brand adds value to the overall manufacturing process.

Shipping and Distribution

Freight Charges

Shipping costs are a significant consideration in the overall expenses associated with manufacturing Jordans. These costs include both the transportation from the manufacturing facility to distribution centers and the shipment of finished products to retail partners. Depending on the distance and shipping method chosen, freight charges can vary, making it essential to optimize shipping logistics to control expenses.

Customs Duties

For international shipments, customs duties and taxes may apply, adding to the manufacturing costs. Compliance with customs regulations and accurately declaring the contents and value of the shipments are crucial to avoid delays and additional expenses. Properly managing customs duties ensures a smooth and cost-effective distribution process.

Warehousing

The warehousing of finished products before their distribution to retail partners or direct consumers incurs additional expenses. The costs include storage space, handling, inventory management systems, and staff. Effectively managing warehousing expenses is vital to ensure efficient order fulfillment and minimize the overall manufacturing costs.

Retail Partnerships

Collaboration with retail partners incurs additional expenses in terms of stocking, marketing, and handling. Costs associated with maintaining relationships with retail partners may include discounts, cooperative advertising, and commissions. These expenses contribute to the overall manufacturing costs of Jordans.

Marketing and Branding

Advertisement Costs

Marketing plays a vital role in promoting Jordans and creating brand awareness. The cost of advertising campaigns, both traditional and digital, is an essential component of the overall manufacturing expenses. Advertising costs include creating marketing materials, media placements, and campaign development. Effective marketing strategies help generate demand and justify the investment in manufacturing.

Sponsorships and Endorsements

Aligning the Jordan brand with high-profile athletes and celebrities through sponsorships and endorsements adds to the marketing and branding expenses. Collaborating with influential figures who embody the essence of the brand helps build credibility and popularity. These partnerships often involve financial commitments that contribute to the overall manufacturing costs.

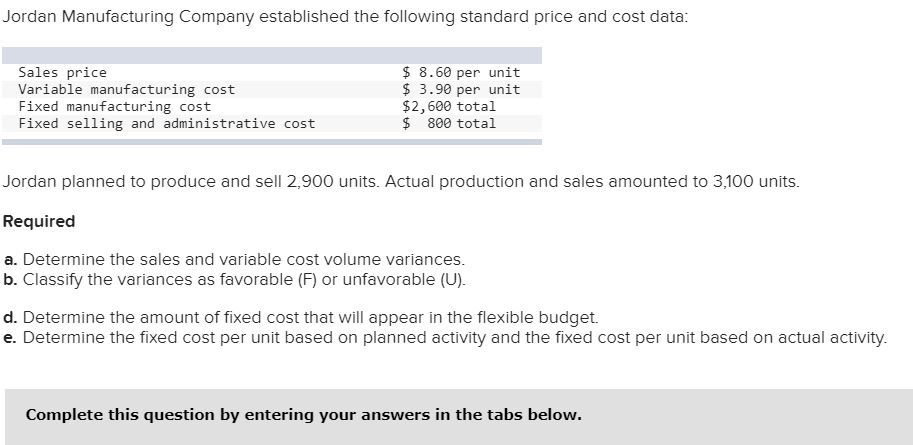

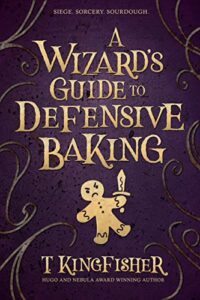

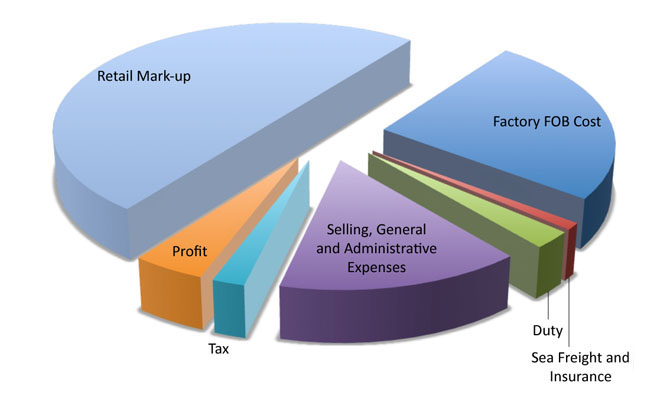

Retail Markup

Wholesale Pricing

The wholesale pricing of Jordans, which is the price at which retailers purchase the shoes from the manufacturer, affects the overall manufacturing costs. Determining the appropriate wholesale price involves considering factors such as production costs, desired profit margins, and market demand. Setting an optimal wholesale price helps balance profitability and competitiveness.

Retailer Profit Margins

Retailer profit margins directly impact the overall manufacturing costs of Jordans. Retail partners mark up the wholesale price to cover their operating expenses, including rent, staff salaries, and marketing costs. The retail markup must be taken into account to ensure the manufacturer’s profitability while also making the shoes competitive in the market.

Production Scale and Volume

Economies of Scale

The scale of production and volume of orders significantly affect the overall manufacturing costs of Jordans. Economies of scale can be achieved through larger production runs, resulting in cost savings due to efficiencies and better utilization of resources. Ordering raw materials and manufacturing in larger quantities can lead to discounts, reducing the per-unit cost of production.

Bulk Orders and Discounts

Manufacturers often receive bulk orders from retailers or distributors. These orders can provide opportunities for discounts on labor, raw materials, and other manufacturing expenses. Negotiating favorable terms with suppliers and retail partners based on the volume of orders allows for cost savings in the manufacturing process.

In conclusion, the manufacturing of Jordans involves extensive research and development, meticulous material selection, and a complex production process. Labor costs, machinery and equipment, overhead expenses, shipping and distribution, marketing and branding, retail markup, and production scale and volume all contribute to the overall cost of manufacturing Jordans. Yet, despite the expenses involved, the high-quality craftsmanship, iconic design, and enduring appeal of Jordans have solidified their status as a sought-after brand in the sneaker industry.