Contents

- Understanding the Basics of Hydraulic Control Valves

- Considerations for Tractor Front End Loaders

- Choosing the Right Type of Hydraulic Control Valve

- Understanding Hydraulic Pressure Ratings

- Flow Rate Considerations

- Controlling Multiple Hydraulic Functions

- Evaluating Control Valve Features

- Importance of Proper Sizing

- Ensuring Compatibility with Hydraulic System

- Cost Considerations

If you’re a tractor owner looking to upgrade your front end loader’s hydraulic control valve, then look no further than the “Choosing the Right Hydraulic Control Valve for Your Tractor Front End Loader” product. With its advanced features and precise control, this hydraulic control valve is designed to enhance the performance and efficiency of your tractor front end loader. Whether you’re working in agriculture, construction, or any other industry, this product is the perfect solution to optimize your equipment’s operation. Say goodbye to inefficient hydraulic systems and hello to improved productivity with this top-notch hydraulic control valve.

Understanding the Basics of Hydraulic Control Valves

What is a hydraulic control valve?

A hydraulic control valve is a crucial component of a hydraulic system. It controls the flow and direction of hydraulic fluid, enabling the operation of various hydraulic functions. These valves ensure that the hydraulic system functions smoothly and efficiently.

How does a hydraulic control valve work?

Hydraulic control valves consist of a body, spools, and ports. The body houses the spool, which slides within the valve to allow or block the flow of hydraulic fluid. The ports are the openings through which the fluid enters and exits the valve. By manipulating the movement of the spool, the operator can control the pressure, flow rate, and direction of the hydraulic fluid.

Types of hydraulic control valves

There are several types of hydraulic control valves available, each with its own unique features and advantages. The three main types are monoblock valves, sectional valves, and load-sense valves.

Considerations for Tractor Front End Loaders

Compatibility with tractor model

When choosing a hydraulic control valve for your tractor front end loader, it is crucial to consider its compatibility with your specific tractor model. Different tractors may have varying hydraulic system specifications and mounting options, so ensure that the valve you choose is designed to fit your tractor correctly.

Load capacity requirements

Another important consideration is the load capacity requirements of your tractor front end loader. The hydraulic control valve you select should be capable of handling the weight and load capacity of your specific application. By choosing a valve with the appropriate load capacity, you can ensure safe and efficient operation.

Pressure and flow rate specifications

It is essential to understand the pressure and flow rate specifications of your hydraulic system when selecting a control valve. The valve you choose should have pressure and flow ratings that align with the requirements of your tractor front end loader. Failure to do so may result in inadequate performance or even damage to the hydraulic system.

Choosing the Right Type of Hydraulic Control Valve

Monoblock valves

Monoblock valves, also known as one-piece valves, are compact and relatively simple to install. They are designed for applications where space is limited and offer a cost-effective solution. Monoblock valves typically have fewer sections and are suited for simpler hydraulic systems.

Sectional valves

Sectional valves are modular in design, allowing for flexibility and customization. They consist of multiple sections that can be combined to create a valve assembly tailored to specific hydraulic requirements. Sectional valves are ideal for complex hydraulic systems that require precise control of multiple functions.

Load-sense valves

Load-sense valves are designed to optimize the hydraulic system’s energy efficiency. They dynamically adjust the flow rate based on the load demand, minimizing wasted energy and reducing heat generation. Load-sense valves are particularly suitable for tractor front end loaders that require efficient control of hydraulic functions.

Understanding Hydraulic Pressure Ratings

Working pressure

Working pressure refers to the maximum pressure that a hydraulic control valve can safely handle during normal operation. It is crucial to choose a valve with a working pressure rating that exceeds the maximum pressure expected in your hydraulic system. This ensures that the valve can withstand the pressure without failure or leakage.

Bursting pressure

Bursting pressure is the maximum pressure that a hydraulic control valve can withstand before it fails catastrophically. While bursting pressure is an important consideration, it is typically higher than the working pressure, ensuring a safety margin. However, it is still essential to select a valve with a bursting pressure rating that meets or exceeds the anticipated system pressures.

Pressure adjustment options

Some hydraulic control valves offer pressure adjustment options, allowing the operator to fine-tune the pressure according to specific requirements. These adjustable valves can be beneficial in applications where precise pressure control is necessary. Consider whether your tractor front end loader requires such a feature when choosing a control valve.

Flow Rate Considerations

Flow rate requirements

The flow rate requirements of your hydraulic system depend on the specific tasks your tractor front end loader needs to perform. Determine the flow rate needed for each hydraulic function, such as lifting, tilting, or extending the loader arms. It is essential to choose a control valve that can provide the required flow rate for efficient operation.

Determining flow rate capacity

To ensure the hydraulic control valve can handle the necessary flow rate, it is crucial to consider both the valve’s maximum flow rate capacity and the overall flow capabilities of the hydraulic system. The valve’s flow rate capacity should be equal to or higher than the highest flow rate required by any of the hydraulic functions in your tractor front end loader.

Balancing multiple functions

Tractor front end loaders often require the simultaneous operation of multiple hydraulic functions. It is important to choose a control valve that can balance the flow rate across these functions. Some valves offer built-in features for flow balancing, ensuring each function receives the appropriate flow rate without compromising performance.

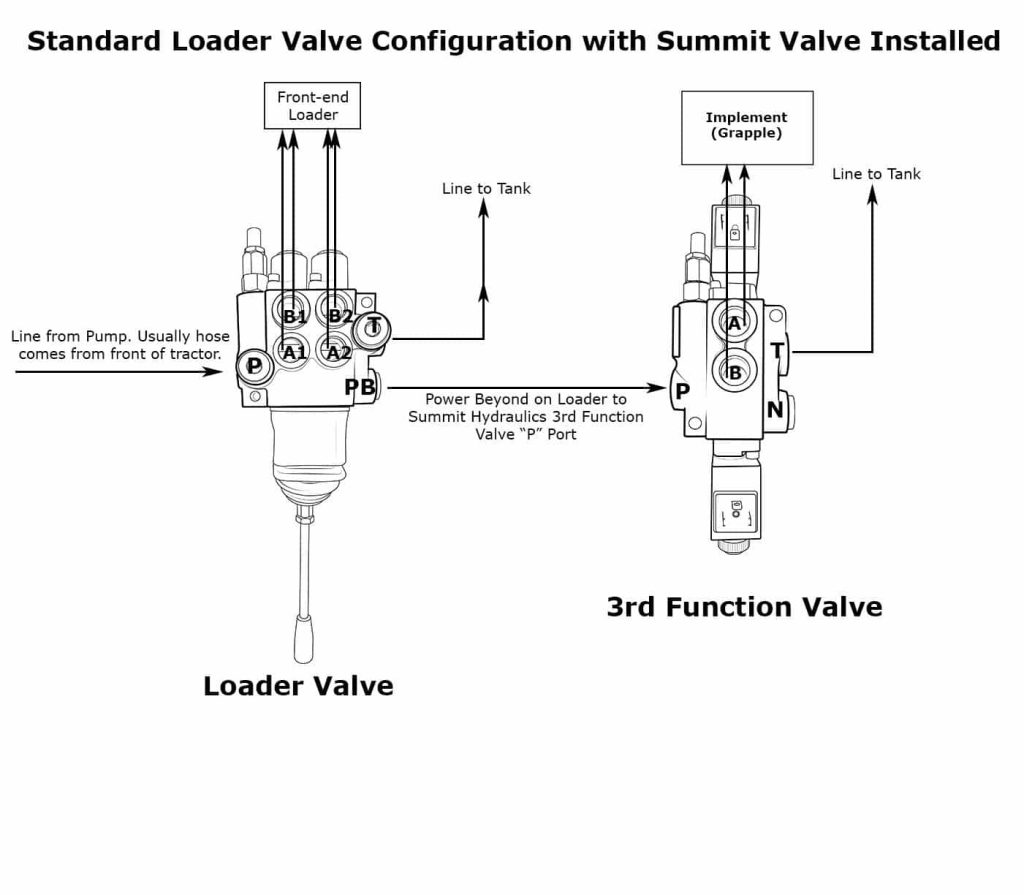

Controlling Multiple Hydraulic Functions

Valve sections and spools

When controlling multiple hydraulic functions, the number of valve sections and available spools become significant. Each valve section and spool corresponds to one hydraulic function. Ensure that the control valve you choose has enough sections and spools to accommodate all the functions required by your tractor front end loader.

Parallel circuit vs series circuit

Hydraulic control valves can be configured in parallel or series circuits. In a parallel circuit, multiple functions operate independently of each other and do not affect the performance of other functions. In a series circuit, the flow rate is shared among multiple functions, and any change in one function may affect the performance of the others. Determine which circuit configuration suits your tractor front end loader’s needs to choose the appropriate control valve.

Priority flow control

Priority flow control is a feature that allows the operator to prioritize one function over others. This can be useful when certain functions require a higher flow rate or immediate response. Consider whether your tractor front end loader requires priority flow control and select a control valve that offers this feature if necessary.

Evaluating Control Valve Features

Manual vs hydraulic operation

Control valves can be operated manually or hydraulically. Manual valves require physical input from the operator, such as turning a lever or knob. Hydraulically operated valves are controlled by hydraulic pressure, eliminating the need for manual manipulation. Consider the convenience and ease of operation when deciding between manual or hydraulic control valves.

Detent options

Detent options refer to the ability of the control valve to maintain the selected position without continuous operator input. Detents provide a hands-free operation and keep the hydraulic functions engaged until intentionally released. Determine if your tractor front end loader requires detent options and choose a control valve that offers this feature if desired.

Shock valves

Shock valves are safety devices that prevent sudden pressure surges or mechanical shocks within the hydraulic system. These valves protect the system components from potential damage caused by abrupt changes in pressure. Assess whether your tractor front end loader requires shock valves and consider selecting a control valve equipped with this safeguard.

Importance of Proper Sizing

Determining the correct valve size

Choosing the correct valve size is crucial for optimal performance and efficiency. Undersized valves may restrict flow and compromise the hydraulic functions’ performance, while oversized valves can lead to excessive pressure drops and inefficiency. Gather the necessary flow rate and pressure specifications of your tractor front end loader to determine the appropriate valve size.

Considerations for future expansion

When selecting a control valve, it is advisable to consider potential future expansion or modifications to your hydraulic system. Will you be adding additional functions or equipment that may require a larger valve? It is prudent to account for possible future needs and choose a control valve that can accommodate any expansions.

Space limitations

Take into account any space limitations when selecting a hydraulic control valve. The valve needs to fit within the available space in your tractor’s hydraulic system without interfering with other components or obstructing access for maintenance. Measure the available space and choose a control valve with dimensions that are compatible with your tractor front end loader.

Ensuring Compatibility with Hydraulic System

Checking hydraulic connections

Before installing a hydraulic control valve, it is essential to ensure compatibility with the hydraulic connections in your tractor front end loader. Consider factors such as thread size, hose diameter, and connection type to ensure a proper fit. Incompatibility can result in leaks or compromised functionality.

Matching valve with pump and cylinder

The control valve must be compatible with the pump and hydraulic cylinders in your tractor front end loader. The flow rate and pressure ratings of the valve should align with the specifications of the pump and cylinders for seamless integration and optimal performance. Check the specifications of your hydraulic components and choose a control valve that matches those requirements.

Avoiding compatibility issues

To avoid compatibility issues, it is wise to consult the manufacturer’s recommendations and guidelines. They can provide valuable insights and assistance in selecting a hydraulic control valve that is compatible with your tractor front end loader’s specific hydraulic system. Consulting with experts or professionals in hydraulic systems can also help ensure compatibility and avoid potential problems.

Cost Considerations

Budget constraints

Budget constraints are a significant factor when choosing a hydraulic control valve. Set a budget for your tractor front end loader’s hydraulic system and consider the cost of the control valve along with other necessary components. It is important to strike a balance between the price and the quality of the control valve to ensure a cost-effective solution.

Quality vs price

While cost is an important consideration, it is equally crucial to prioritize the quality and reliability of the control valve. Choosing a high-quality valve may require a higher initial investment but can result in long-term cost-effectiveness due to its durability and performance. Evaluate the reputation of the manufacturer and the materials used in the valve’s construction when making your decision.

Long-term cost-effectiveness

Consider the long-term cost-effectiveness of the control valve. A well-built and properly selected valve can offer reliable performance, reducing the need for frequent repairs or replacements. Additionally, investing in a control valve with features that improve energy efficiency, such as load-sense valves, can result in long-term cost savings by minimizing fuel consumption and reducing overall operating costs.

In conclusion, understanding the basics of hydraulic control valves is crucial when choosing the right valve for your tractor front end loader. Consider factors such as compatibility with your tractor model, load capacity requirements, pressure and flow rate specifications, as well as the various types of control valves available. Evaluate control valve features, sizing requirements, and compatibility with your hydraulic system while considering budget constraints and long-term cost-effectiveness. By taking these considerations into account, you can select the most suitable hydraulic control valve that will ensure efficient and reliable operation of your tractor front end loader.