Contents

Are you in the market for a new front end loader bucket for your tractor? Look no further! Our product, “Choosing the Right Front End Loader Bucket for Your Tractor,” is designed to assist you in finding the perfect bucket to meet your needs. Whether you require a bucket for digging, lifting, or carrying materials, our product provides valuable information and guidance to ensure you make the right choice. Save yourself time and effort by investing in the ideal front end loader bucket for your tractor today!

Choosing the Right Front End Loader Bucket for Your Tractor

Are you in the market for a new front end loader bucket for your tractor? With so many options available, it can be overwhelming to decide which one is the right fit for your needs. However, if you consider the following factors, you can make a more informed decision and find the perfect bucket for your tractor.

Compatibility with Tractor

One of the first factors to consider is the compatibility of the front end loader bucket with your tractor. This includes the size and type of your tractor, as well as the mounting system and hydraulic connections.

Tractor Size and Type

Not all front end loader buckets are suitable for every tractor. The size and type of your tractor will determine which buckets are compatible. Make sure to check the specifications of the bucket and ensure it is designed to fit your specific tractor model.

Mounting System

The mounting system of the bucket is another important aspect to consider. The bucket should have a mounting system that is compatible with your tractor’s front end loader arms. Be sure to check if the mounting system is universal or specific to certain tractor brands.

Hydraulic Connections

In addition to the mounting system, you should also verify that the hydraulic connections of the front end loader bucket match those of your tractor. This ensures that you can seamlessly connect the bucket to your tractor’s hydraulic system and operate it efficiently.

Bucket Size

The size of the front end loader bucket plays a crucial role in determining its functionality and efficiency. Consider the volume capacity, width and depth, and height of the bucket when making your decision.

Volume Capacity

The volume capacity refers to the amount of material the bucket can hold. It is usually measured in cubic feet or cubic yards. Choose a bucket with a volume capacity that aligns with the type and volume of materials you typically handle. Keep in mind that a larger capacity may also increase the weight of the bucket.

Width and Depth

The width and depth of the bucket are important factors to consider, especially when working in tight spaces or with specific types of materials. A wider bucket allows you to move more material at once, while a deeper bucket may be necessary for handling denser materials.

Height

The height of the front end loader bucket determines the maximum reach and tipping angle when dumping. Consider the height in relation to your specific needs, such as how high you need to dump materials and the reach required for efficient loading and unloading.

Material and Design

The material and design of the front end loader bucket play a significant role in its durability and effectiveness. Consider factors such as the choice between steel and aluminum, bucket shape, reinforcements, and whether it is smooth or ribbed.

Steel vs. Aluminum

Front end loader buckets are commonly made from either steel or aluminum. Steel buckets are generally more durable and better suited for heavy-duty tasks and abrasive materials. Aluminum buckets, on the other hand, are lighter and more resistant to corrosion. Consider your specific needs and the type of materials you typically handle when choosing between steel and aluminum.

Bucket Shape

The shape of the bucket can vary significantly between different models. Some buckets have a standard design with a flat bottom and straight sides, while others may have a curved or tapered shape. The shape of the bucket can affect how efficiently it scoops and dumps materials, so choose one that suits your specific requirements.

Reinforcements

Front end loader buckets often have reinforcements in strategic areas to enhance their strength and durability. These reinforcements can include additional plates, gussets, or braces. Consider the quality and placement of the reinforcements when evaluating different bucket options.

Smooth or Ribbed

Some buckets have a smooth interior surface, while others have a ribbed texture. A smooth bucket can make it easier to unload materials completely and may be better suited for certain applications. Conversely, a ribbed bucket can provide better grip and traction when handling loose or slippery materials. Consider the type of materials you typically work with and choose a bucket with the appropriate interior surface.

Weight Capacity

The weight capacity of the front end loader bucket is an essential factor to consider, especially if you frequently handle heavy loads. Pay attention to the maximum load rating, weight distribution, and impact resistance of the bucket.

Max Load Rating

Every front end loader bucket has a maximum load rating that indicates the weight it can safely handle. Exceeding this limit can lead to damage or failure of the bucket. Consider the maximum load rating and ensure it aligns with the weight of the materials you typically handle.

Weight Distribution

Proper weight distribution is crucial to maintain the balance and stability of your tractor when using a front end loader bucket. The bucket should be designed in such a way that the weight is evenly distributed over the front wheels of your tractor. This ensures safe and efficient operation.

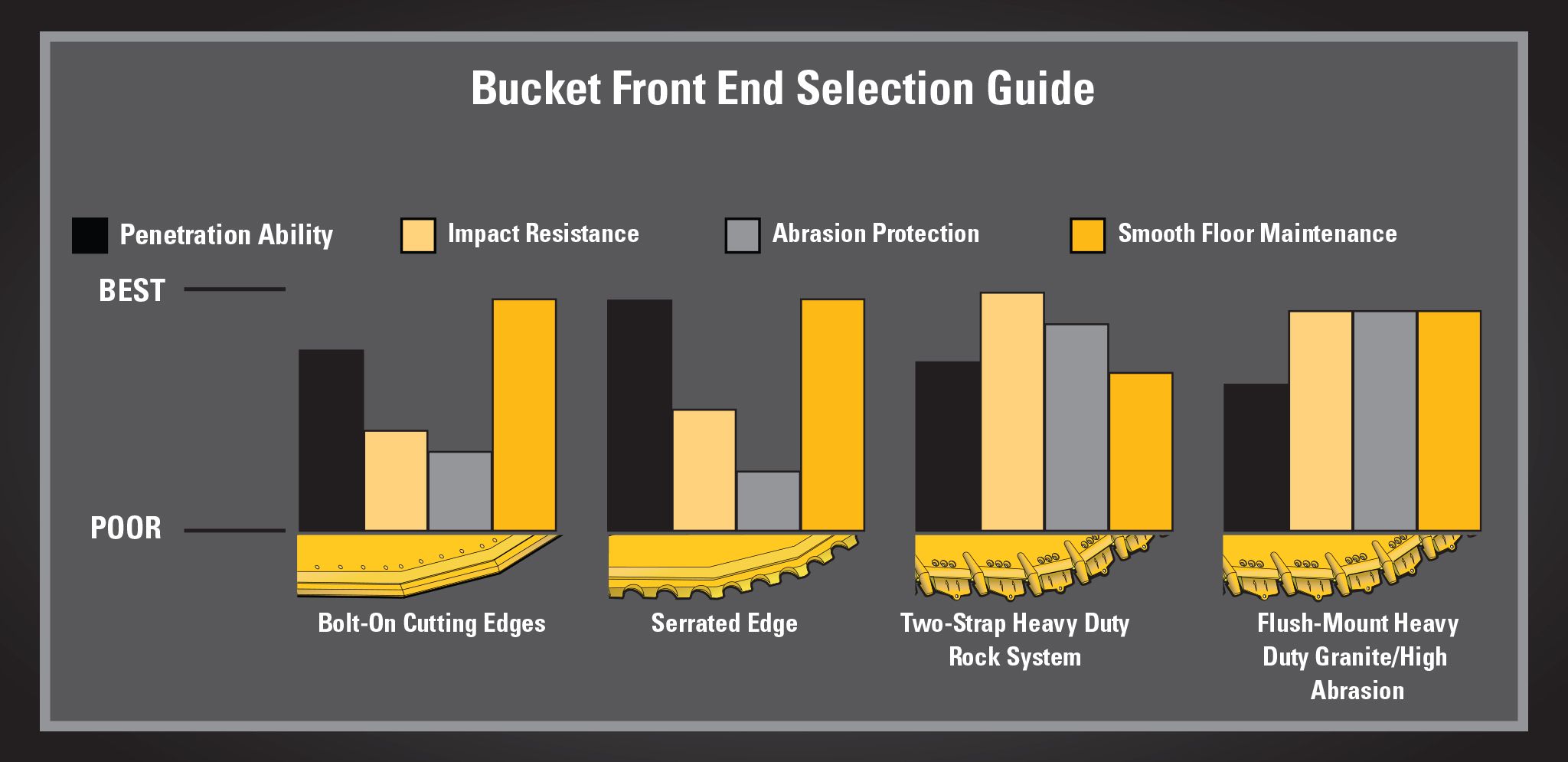

Impact Resistance

Front end loader buckets are subjected to significant wear and tear, especially when working with heavy or abrasive materials. Opt for a bucket that offers high impact resistance to withstand these harsh conditions. Look for features such as reinforced edges and wear-resistant materials to ensure the longevity of the bucket.

Dump Angle

The dump angle of the front end loader bucket determines the degree of tilt, dump height, and dump reach. This factor is particularly important when considering the type of work you will be performing with the bucket.

Degree of Tilt

The degree of tilt refers to how far the bucket can tilt forward or backward. A greater tilt angle allows for more efficient dumping and ensures that the materials are fully discharged from the bucket. Consider the specific tasks you need to perform and choose a bucket with an appropriate degree of tilt for optimal functionality.

Dump Height

Dump height is the vertical distance at which the bucket can lift and dump materials. This is an important consideration when working with high-sided trucks or containers. Ensure that the dump height of the bucket is sufficient for your needs and allows for easy and safe dumping of materials.

Dump Reach

Dump reach refers to the horizontal distance at which the bucket can extend when dumping. This is useful when working in confined spaces or when the dumping location is not directly in front of the tractor. Consider the dump reach of the bucket and choose one that allows for efficient dumping in your specific work environment.

Bucket Teeth

Bucket teeth are essential for gripping and digging into materials, especially when working with soil, gravel, or other loose materials. Consider the type of teeth, their replaceability, and the angle at which they are positioned on the bucket.

Tooth Types

Front end loader buckets can come with different types of teeth, such as standard digging teeth, rock teeth, or bolt-on teeth. The type of teeth you choose depends on the materials you primarily work with. Standard digging teeth are versatile and suitable for most applications, while rock teeth provide better durability and performance when handling rocky terrain.

Replaceability

Over time, the bucket teeth may wear down or break. It’s important to choose a bucket that allows for easy replacement of teeth. Look for options that offer replaceable teeth or a tooth system that can be easily maintained.

Tooth Angle

The angle at which the teeth are positioned on the bucket can affect their effectiveness in gripping and digging. Choose a bucket with teeth that have the appropriate angle for the type of materials you handle. Teeth with a more aggressive angle are better suited for digging and penetrating hard soil or rock, while a shallower angle may be sufficient for softer materials.

Ease of Attachment

The ease of attaching and detaching the front end loader bucket is an important factor to consider, as it can greatly enhance your efficiency and productivity. Look for features such as a quick attach system, compatibility with loader arms, and ease of removal.

Quick Attach System

A quick attach system allows for easy and efficient attachment of the bucket to the loader arms. This eliminates the need for time-consuming and cumbersome manual connection methods. Look for buckets that offer a reliable and user-friendly quick attach system for effortless attachment and detachment.

Compatibility with Loader Arms

Ensure that the front end loader bucket is compatible with the loader arms of your tractor. Check the specifications and dimensions of the bucket to verify that it can be securely and effectively attached to your loader arms. Compatibility issues can lead to instability and compromise the safety and functionality of the bucket.

Ease of Removal

In addition to attachment, consider the ease of removing the front end loader bucket when necessary. Whether you need to switch to a different attachment or remove the bucket for maintenance purposes, a design that allows for quick and hassle-free removal can save you valuable time and effort.

Versatility

The versatility of the front end loader bucket should also be taken into account when making your decision. Consider the attachment options, the ability to handle different materials, and the capacity to perform various tasks.

Attachment Options

Some front end loader buckets offer additional attachments or accessories that can expand their functionality. These could include things like grapple attachments, forks, or snow blades. If you anticipate needing additional attachments in the future, choose a bucket that offers compatibility with these options.

Ability to Handle Different Materials

Different front end loader buckets are designed to handle specific types of materials. Consider the materials you work with regularly and ensure that the bucket you choose is capable of efficiently handling them. Some buckets are designed specifically for handling gravel, while others excel at moving loose soil or snow.

Ability to Perform Various Tasks

Depending on your needs, you may require a front end loader bucket that can perform a variety of tasks. Look for options that offer features such as adjustable bucket angles, detachable teeth, or the ability to switch between different bucket configurations. This allows you to adapt the bucket to different tasks and maximize its versatility.

Cost

While cost should not be the only factor influencing your decision, it is certainly an important consideration. Front end loader buckets can vary significantly in price, depending on their size, material, and features. Set a budget and consider the value that each bucket offers based on its specifications and capabilities. Remember that investing in a high-quality bucket that meets your needs can save you money in the long run by ensuring durability and efficiency.

Manufacturer Reputation

Lastly, consider the reputation of the manufacturer when choosing a front end loader bucket for your tractor. Conduct thorough research on different manufacturers, read customer reviews, and consider the warranty and support offered by each brand. A reputable manufacturer is more likely to produce a reliable and high-quality product, ensuring your satisfaction and peace of mind.

In conclusion, choosing the right front end loader bucket for your tractor involves considering several factors. Evaluate the compatibility of the bucket with your tractor, the size, material, and design of the bucket, the weight capacity, dump angle, and bucket teeth. Additionally, consider the ease of attachment, versatility, cost, and the manufacturer’s reputation. By carefully assessing these factors, you can select a front end loader bucket that meets your specific needs and enhances the functionality and productivity of your tractor.