Contents

- 1. The Importance Of Bandsaw Guides For Precision Cuts

- 2. Understanding The Different Types Of Bandsaw Guides

- 2.1. Roller Guides

- 2.2. Blade Guides

- 2.3. Stabilizer Guides

- 3. Tips And Techniques For Proper Bandsaw Guide Setup

- 3.1. Adjusting Roller Guides

- 3.2. Fine-Tuning Blade Guides

- 3.3. Setting Up Stabilizer Guides

- 4. Maintaining And Troubleshooting Bandsaw Guides

- 4.1. Cleaning And Lubricating Guides

- 4.2. Identifying And Resolving Common Issues

- 5. Enhancing Bandsaw Performance With Carter Guides

- Frequently Asked Questions Of Carter Bandsaw Guides: Enhancing Precision In Bandsaw Use

- Conclusion

Carter bandsaw guides enhance precision in bandsaw use by providing accurate and exact guidance. With these guides, users can achieve precise cuts and improve their overall woodworking experience.

Woodworking enthusiasts understand the importance of precision when working with a bandsaw. Whether it’s creating intricate designs, trimming irregular shapes, or simply cutting through thick materials, accuracy is key. That’s where carter bandsaw guides come into play. These guides are specially designed to enhance the precision of bandsaw use, ensuring that every cut is accurate and exact.

With their unique features and innovative design, carter bandsaw guides provide woodworkers with the confidence and control they need to achieve exceptional results. We will explore the benefits of carter bandsaw guides and how they can revolutionize your woodworking projects.

Credit: www.midwesttechnology.com

1. The Importance Of Bandsaw Guides For Precision Cuts

Bandsaw guides play a crucial role in enhancing precision during the cutting process. By providing support and guidance to the blade, bandsaw guides ensure that the blade maintains a consistent and accurate path, resulting in precise cuts. These guides prevent the blade from wandering, keeping it aligned and stable.

They also help reduce friction, ensuring smoother and more efficient cutting. With the guidance of bandsaw guides, woodworkers can achieve accurate and clean cuts, leading to higher quality finished products. Whether it’s straight cuts or intricate curves, bandsaw guides are essential for maintaining precision throughout the cutting process.

Remember, using the right bandsaw guides can significantly enhance the overall performance of a bandsaw, effectively improving the accuracy and quality of the cuts.

2. Understanding The Different Types Of Bandsaw Guides

Carter bandsaw guides are an essential tool for enhancing precision in bandsaw use. Understanding the different types of bandsaw guides is crucial to optimize performance. Let’s begin with an introduction to carter bandsaw guides. These guides are known for their exceptional quality and craftsmanship.

They offer numerous benefits, including increased accuracy, reduced blade friction, and improved stability. With carter bandsaw guides, woodworkers can achieve cleaner cuts and minimize blade drift. Available in various models to fit different bandsaw types, carter guides are durable and designed to withstand continuous use.

Whether you’re a professional or a hobbyist, investing in carter bandsaw guides can significantly improve your bandsawing experience. Say goodbye to inaccuracies and embrace the precision that carter bandsaw guides bring to your woodworking projects.

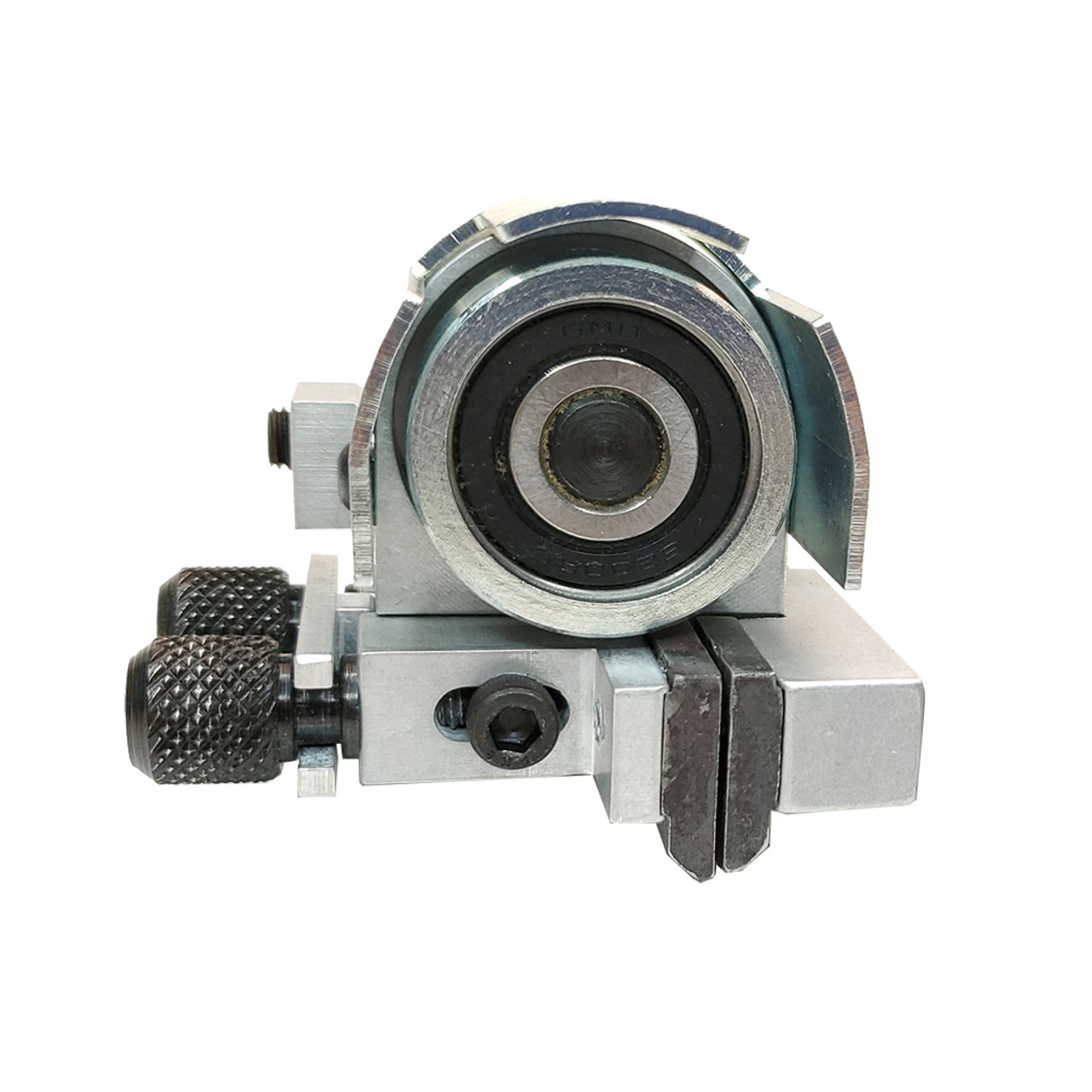

2.1. Roller Guides

Roller guides are an essential component of carter bandsaw guides, enabling enhanced precision in bandsaw use. These guides feature a unique design that reduces friction and ensures smooth operation during cutting. By effectively supporting the blade, roller guides contribute to accurate and clean cuts.

They also minimize blade vibration, resulting in improved cutting stability and reduced material wastage. With their durability and reliability, roller guides are ideal for both professional woodworkers and hobbyists seeking precision and efficiency in their bandsaw projects. Additionally, these guides are easily adjustable, allowing users to achieve precise blade tracking and optimal performance.

Overall, roller guides are an indispensable accessory for bandsaw users looking to enhance the accuracy, consistency, and overall quality of their cuts.

2.2. Blade Guides

1. Blade guides play a crucial role in ensuring heightened precision and accuracy in bandsaw use. 2. By understanding their function, users can reap the full benefits of carter blade guides. 3. These guides ensure that the blade is properly aligned, reducing the risk of drift or wandering.

4. With precise alignment, woodworkers can achieve cleaner cuts and minimize material wastage. 5. Carter blade guides also reduce friction, resulting in smoother cutting and enhanced blade life. 6. Woodworkers will appreciate the improved control and stability offered by these guides.

7. Enhanced accuracy, coupled with reduced blade wear, makes carter blade guides a valuable investment. 8. From hobbyists to professionals, anyone seeking precision in bandsaw use can benefit from these guides. 9. So why settle for subpar performance when you can take advantage of the carter bandsaw guides?

10. Elevate your woodworking experience with these powerful guides and unlock your bandsaw’s true potential.

2.3. Stabilizer Guides

Carter stabilizer guides play a crucial role in bandsaw precision. These guides ensure stability and accuracy, which are essential for achieving the desired results. By minimizing blade deflection and eliminating vibration, stabilizer guides enhance the overall performance of bandsaws. They provide better control over the blade, preventing it from wandering during cuts.

Furthermore, these guides are specifically designed to accommodate various applications, such as resawing, cutting curves, and making intricate cuts. Whether you are a professional woodworker or a hobbyist, using carter stabilizer guides can significantly improve the quality of your work.

Their ability to reduce blade drift and increase cut accuracy make them indispensable tools in the bandsawing process. So, if you want to enhance precision and achieve better results with your bandsaw, investing in carter stabilizer guides is definitely worth it.

3. Tips And Techniques For Proper Bandsaw Guide Setup

Proper bandsaw guide setup is crucial for achieving optimal performance with your carter bandsaw guides. To assist you, here is a step-by-step guide for installing them. Firstly, make sure to carefully follow these instructions for precise installation. Next, ensure that the guides are aligned properly and securely attached.

You’ll also want to adjust the blade to fit snugly within the guides. Moreover, check that the guides are parallel to the blade’s teeth for accurate cutting. Additionally, it’s important to regularly inspect and maintain the guides to keep them in optimum condition.

By implementing these tips and techniques, you can enhance the precision of your bandsaw use and enjoy outstanding results with your carter bandsaw guides.

3.1. Adjusting Roller Guides

Adjusting roller guides is an essential part of maximizing the precision of your carter bandsaw. By understanding the process of adjusting roller guides, you can ensure optimal performance for different cutting tasks. For various cutting tasks, there are common adjustments that need to be made.

These adjustments may include setting the blade height, adjusting the roller guides’ position, and aligning the blade with the guides. By making these adjustments, you can enhance the accuracy and efficiency of your bandsaw. It’s important to remember to regularly check and adjust the roller guides to maintain their effectiveness.

Taking the time to understand and properly adjust the roller guides will result in better cuts and overall improved bandsaw performance.

3.2. Fine-Tuning Blade Guides

Fine-tuning blade guides is essential for achieving precise cuts with carter bandsaw guides. To align and adjust the blade guides, consider these helpful tips. Begin by ensuring the guides are in proper alignment with the blade. Take note of any inconsistencies and make necessary adjustments.

Next, check the side-to-side position of the guides, ensuring they are evenly spaced around the blade. Make small adjustments as needed. To further enhance precision, adjust the height of the guides to match the thickness of the material being cut.

This will minimize deflection and improve accuracy. Lastly, ensure the guides are properly lubricated to reduce friction and promote smooth operation. By following these guidelines, you can optimize your blade guide setup and achieve outstanding results with your bandsaw.

3.3. Setting Up Stabilizer Guides

Proper positioning and setup of stabilizer guides is crucial to ensure precision during bandsaw use. By following the recommended guidelines for carter bandsaw guides, you can enhance your cutting accuracy. Start by carefully positioning the stabilizer guides in relation to the blade.

Make sure they are aligned parallel to the blade and close enough to provide support. Addressing common issues such as blade deflection or vibration can also improve the performance of the bandsaw. If you notice any problems, check the position of the stabilizer guides to ensure they are not causing the issue.

Troubleshooting tips may include adjusting the tension, replacing worn-out parts, or lubricating the guides for smoother operation. With proper setup and troubleshooting techniques, you can optimize the precision of your bandsaw cuts.

4. Maintaining And Troubleshooting Bandsaw Guides

Regular maintenance is crucial for ensuring the accuracy and precision of carter bandsaw guides. By performing routine upkeep, you can enhance the overall performance of your bandsaw. Keep in mind that troubleshooting techniques play a vital role in maintaining these guides.

When faced with issues, it’s important to address them promptly and effectively. By following the recommended maintenance and troubleshooting practices, you can maximize the accuracy and reliability of your bandsaw guides. This will help you achieve precise cuts and improve the overall quality of your woodworking projects.

With proper care and attention, carter bandsaw guides can provide you with exceptional results for years to come.

4.1. Cleaning And Lubricating Guides

Proper care and maintenance of bandsaw guides is essential to ensure smooth operation. Regular cleaning and lubrication are key steps in enhancing precision and extending the lifespan of your carter bandsaw guides. To keep them in optimal condition, follow these recommended lubrication techniques.

Firstly, remove any debris or buildup from the guides using a brush or compressed air. Next, apply a few drops of lubricant to the guide bearings, making sure to distribute it evenly. Avoid over-lubricating as it can attract more dust and debris.

Additionally, regularly check the guides for wear and tear, and replace them if necessary. Remember to follow the manufacturer’s guidelines for lubricant selection and frequency of maintenance. By taking proper care of your carter bandsaw guides, you can improve accuracy and efficiency in your bandsaw use.

4.2. Identifying And Resolving Common Issues

Carter bandsaw guides are essential in achieving precise cuts with your bandsaw. In order to maximize their effectiveness, it’s important to identify and resolve common issues that may arise. When troubleshooting guide problems, keep these tips and solutions in mind.

First, check for misalignment, ensuring that the guides are properly positioned. If the guides are too tight or too loose, adjust them accordingly to avoid blade wandering. Next, inspect for wear and tear, such as damaged bearings or worn-out rub blocks, and replace them if necessary.

In addition, make sure the guides are clean and free from sawdust or debris buildup, as this can affect their performance. Regular maintenance and lubrication are also important to keep the guides in optimal condition. By addressing these issues promptly, you can enhance the precision of your bandsaw cuts and improve overall performance.

5. Enhancing Bandsaw Performance With Carter Guides

Carter bandsaw guides play a crucial role in enhancing the precision and performance of bandsaws. By eliminating blade drift and ensuring proper blade alignment, these guides contribute to a better woodworking experience. With carter guides, woodworkers can achieve accurate cuts and intricate designs with ease.

The overall impact of these guides is truly remarkable, as they improve the efficiency and effectiveness of bandsaw use. They provide stability and control, resulting in cleaner cuts and reduced waste. Carter bandsaw guides are designed to withstand heavy usage and offer long-lasting durability.

Whether you are a professional woodworker or a hobbyist, incorporating carter guides into your bandsaw setup can significantly enhance the quality of your work. Upgrade your bandsaw with carter guides and experience the difference it makes in your woodworking projects.

Frequently Asked Questions Of Carter Bandsaw Guides: Enhancing Precision In Bandsaw Use

What Are Carter Bandsaw Guides?

Carter bandsaw guides are innovative accessories that enhance the precision of bandsaw use. These guides are designed to stabilize the blade, prevent wavering, and increase cutting accuracy. They are essential for woodworkers and professionals who seek exceptional results in their bandsaw projects.

How Do Carter Bandsaw Guides Work?

Carter bandsaw guides work by controlling the lateral movement of the bandsaw blade during cutting. They consist of precision bearings that support the blade and keep it in alignment. This feature reduces friction, minimizes vibration, and allows for cleaner, more accurate cuts on a variety of materials.

What Are The Benefits Of Using Carter Bandsaw Guides?

Using carter bandsaw guides offers numerous benefits. They improve cutting accuracy, resulting in smoother finishes and reduced waste. They also extend blade life, reduce noise and vibration, and enhance overall safety during operation. These guides are a must-have for professionals and hobbyists seeking precision in their bandsaw work.

Can Carter Bandsaw Guides Be Used On Any Bandsaw Model?

Carter bandsaw guides are designed to be versatile and compatible with various bandsaw models. However, it’s important to check the specifications and compatibility of the guides with your specific bandsaw before purchasing. Manufacturers often provide compatibility information to help users determine if the guides will fit their machine.

How Easy Is It To Install Carter Bandsaw Guides?

Installing carter bandsaw guides is generally straightforward and user-friendly. The guides come with clear instructions and mounting hardware, making the installation process hassle-free. With a bit of patience and basic tools, even beginners can successfully install these guides and start benefiting from their precision and performance enhancements.

Where Can I Purchase Carter Bandsaw Guides?

Carter bandsaw guides can be purchased from various reputable woodworking tool retailers, both online and offline. It’s advisable to check with local woodworking supply stores or trusted online platforms that specialize in bandsaw equipment and accessories. Ensure you purchase genuine carter bandsaw guides to guarantee quality and compatibility.

Conclusion

To sum it up, carter bandsaw guides offer a game-changing solution for bandsaw users, enhancing precision and efficiency like never before. With their innovative design and high-quality materials, these guides provide reliable support and smooth blade operation, resulting in cleaner cuts and reduced waste.

The adjustable nature of carter bandsaw guides caters to various thicknesses and sizes, ensuring versatility and adaptability for different woodworking projects. Whether you are a professional woodworker or a hobbyist, these guides are essential in enhancing the accuracy and overall performance of your bandsaw.

By minimizing blade deflection and maximizing control, carter bandsaw guides enable you to achieve the level of precision you need for intricate woodworking tasks. Don’t settle for subpar results when you can elevate your bandsaw experience with carter bandsaw guides.

Start experiencing the benefits of enhanced precision and take your woodworking skills to the next level.